|

| |

|

|

| |

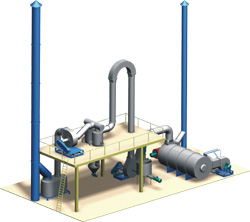

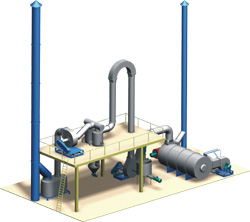

| Spray

dryers are offered for feeds in liquid form containing

either water or any other solvent. Feeds may be solution,

slurry or emulsion. Depending on the particle size of

the final product required and the nature of feed any

one or combination of following atomization system is

used. |

| |

|

Two fluid atomization. |

|

High pressure

single fluid atomization. |

|

Rotary disc atomization. |

|

|

|

|

|

| |

|

|

The final product

obtained from spray dryer is in powder form. By varying the

operating parameters of the spray dryer the required powder

characteristics such as moisture, particle size, bulk density,

flowability, Particle Morphology etc. can be achieved.

Besides manual and semi-automatic systems

we offer PLC and SCADA based systems for easy operation

and monitoring of spray dryer. Multiple systems can be operated

from a single computer thus reducing the manpower requirement.

All the important parameters like temperatures, pressures,

flow etc. are recorded and displayed in the system and can

be retrieved at any given moment.

Capacity: The spray dryers having

water evaporation capacity ranging from 1kg/hr to 18,000 kg/hr

can be offered and supplied. |

|

| |

| Operating temperatures:

The spray dryers having operating temperatures up to 1100°C

can be offered and supplied.

CIP Systems: We offer integrated cleaning

in place (CIP) systems in the spray dryers for automatic and

fast cleaning of the complete system. This feature is essential

where multiple products are dried in a single system and frequent

washing is required.

Typical applications of spray dryer are Dyestuffs,

pigments, starch, detergents, milk powder, fruits, pharmaceutical,

herbal extracts, food flavors, ceramics, china clay, enzymes

etc. |

|

|

|

|

| |

| ------------------------------------------------------------------------------------------------------------------------------------- |

| |

|

|

| |

|

Flash dryers are used for drying of wet cakes

which are sensitive to heat. There are different

variations of flash dryers available depending

upon the need to disperse the wet cake or pastes.

These are:

Spin Flash Dryer

This consists of a horizontal agitator, which

disperses the feed while it comes in contact with

the hot air and gets dried. |

|

|

|

|

| |

|

|

Cage

Mill Flash Dryer

This consists of a vertical pin type rotary and stationary

cages. The wet feed is fed at the center of the rotating

cage, where it comes in contact with hot air. The rotating

cage disperses the feed while drying.

Due to very low residence time in the

range of 0.5 to 2 seconds in the flash dryers, heat

sensitive products can be easily dried without degradation.

Particle size of the final product

can be controlled by installing a particle size controller

which recycles the larger particle size back to the

agitator and allows only the pre-determined size particles

to be discharged as product. |

|

| |

| Capacity:

We can offer the flash dryers having capacities of 10kg/hr

to 50000kg/hr product rate.

Typical applications of flash dryer are starch,

bagasse, minerals, pigments and dyes, phosphates, etc. |

| |

Raj Process Equipments pioneer

in Tube Bundle Dryer Manufacturers India can flash dry heat sensitive

products with Spin Flash Dryer and Cage Mill Flash Dryer.DDGS

Dryers Manufacturers India have capacities of 10kg/hr to 50000kg/hr. |

| |

|

| |

| ------------------------------------------------------------------------------------------------------------------------------------- |

| |

|

|

|

| |

|

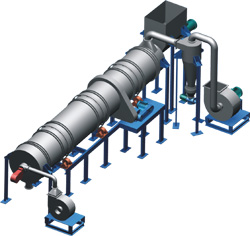

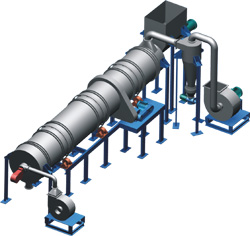

Rotary dryers are used for drying wet powders

and cakes, which are easily breakable and dispersible.

The rotary dryer consists of a rotating drum with

angle lifting blades which lift the feed as the

drum rotates and showers it in the stream of hot

air flowing through the drum.

The rotary dryers can be used

as calciners using direct or indirect firing.

GMP plants are offered for pharmaceutical,

food, and biochemical applications.

|

|

|

|

|

| |

|

|

Capacity:

We can offer the rotary dryers with capacity range

from 100kg/hr to 50000kg/hr product rate and operating

temperatures up to 600°C.

Typical applications of rotary dryers

include silica sand, bagasse, minerals, coconut powder,

etc. |

|

|

| |

|

| |

| ------------------------------------------------------------------------------------------------------------------------------------- |

| |

|

|

| |

| The

process air is supplied to the bed through

a special perforated distributor plate and

flows through the bed of solids at a velocity

sufficient to support the weight of particles

in a fluidized state. Bubbles form and collapse

within the fluidized bed of material, promoting

intense particle movement. In this state,

the solids behave like a free flowing boiling

liquid |

| |

|

Advanced

method of drying wet/semi wet solids

|

|

Unlike in Tray Drying every solid particle

is floating in the HOT STREAM of |

| |

Air which is blown from

down to up creating material layer in

fluidised |

| |

state |

|

|

Almost every

wet particle directly receives the heat

energy from hot Air |

| |

resulting in uniform

and quick drying |

|

|

|

|

|

|

| |

| Features of RAJ Continuous

Fluid Bed Dryers : |

| |

|

Very versatile process equipment

for uniform and efficient drying of products. |

|

Fully automatic

operation based on PLC control / without PLC control |

|

Minimum handling and more

hygienic |

|

Lifting & tilting device

of product container for easy handling |

|

Option - steam heated or electric

heated blower |

|

cGMP model with documentation

as option. |

|

| |

| Material

of Construction:

AISI 304 / AISI 316 / Custom made.

Accessories:

Heat recovery unit can be incorporated, cyclone, bag filters,

multiclones, wet scrubber

Applications:

Chemical / Fertilizer / Food - salt, sugar / Mineral - Sand,

Aluminum / Ore calcining / Metal oxidation / Sludge Incineration

/ Pyrolysis of Plastic Waste / Pigment etc.

Capacity available from 5 kg/hr to 2000 kg/hr

water/solvent evaporation. |

| |

|

| |

| ------------------------------------------------------------------------------------------------------------------------------------- |

| |

|

|

| |

|

Operating Principle |

| |

| The

wet feed is continuously agitated

by the heated rotating blades, thus

exposing new areas to heating surfaces.

This results in the moisture boiling

off and rendering the material to

dry to the required degree. |

| |

| Features

of RAJ Paddle Dryer : |

| |

|

Low

running cost – contact dryer. |

|

Continuous production machine

without human touch. |

|

Ideal

for solvent recovery. |

|

Suitable

for Crystalline material. |

|

On-line

particle size reduction –

no separate pulverizer required. |

|

Factory

assembled & tested. |

|

Compact

construction – less floor

area. |

|

Choice

of heating medium – steam,

hot water. |

|

Minimum

exhaust air quantity – no

elaborate air cleaning equipment

|

| |

needed. |

|

Absence

of high speed rotating parts –

less breakdowns. |

|

Special

paddle form – ploughing and

self cleaning action. |

|

Initial

particle size is maintained. |

|

| |

| Typical

Applications |

| |

|

Crystaline

Solids |

|

Pasty

Solids |

|

Sludge |

|

Agro

Waste |

|

Magnesium

Carbonate |

|

Polypropylene

Beads |

|

|

|

|

|

|

|

| |

| ------------------------------------------------------------------------------------------------------------------------------------- |

| |

|

|

| Operation

is fully automatic with low maintenance. |

| |

Steam

Tube Bundle Dryers are based on the

conduction mode for drying. The product

to be heated and dried only contacts

steamheated tubes, and not directly

steam. Tube bundles are operated on

the counter-flow principle (i. e.

steam flows in the direction opposite

to the direction of the material flow).

The Tube Bundle Dryers are designed

by considering the wet and dry product

flow characteristics, lump crust formation

tendency and thermal sensitivity of

the material in dry condition. |

| |

| Indirect

Steam Tube Rotary Dryer |

In

Indirect Steam Tube Rotary Dryer the

tubes are arranged in a circumferential

manner on the inner periphery of the

rotating shell. This entire shell

and tubes assembly is supported on

tyres / rollers & driven throughsuitable

gear drive. Wet feed material is fed

through material inlet nozzle installed

at one end of the shell of dryer.

This wet feed is fed through Screw

Feeder. Feed material showered on

the tubes with the help of lifting

blades which are mounted on the rotating

shell. Steam enters in the tubes through

rotating joint installed at material

discharge end of the shell. Material

gets dried & discharged from the

material discharge ports on the shell.

Vapours are removed from the feed

end with the help of suction blower

after separating fines in the cyclone

separator. The suitable sealing arrangement

is provided to prevent air leakage

and product \losses. |

| |

|

|

|

| Rotary Tube

Bundle Dryers |

|

In

Rotary Tube Bundle Dryer the Tube Bundle is rotated

inside the stationary insulated housing. Steam

is passed though one end of Tube Bundle for drying

and condensate is removed from the other end.Wet

feed Material to be dried is fed into the stationary

dryer housing from Feed Nozzle at one end. The

material gets lifted up & showered on tubes

with the help of lifting blades provided on tube

bundle periphery. Material gets dried by conduction

heat transfer & it is discharged from the

other end. |

| |

|

| RAJ offers customized

configurations of Steam Tube Dryers : |

|

Vapor Exhaust

: Natural Draft / Induced Draft. |

|

Fines Recovery : Cyclones

/ Bag Filters / Settling Chambers. |

|

Heating Media : Steam / Hot

Oil. |

|

Feed preconditioning, Product

backmixing systems. |

|

Feed & product handling,

conveying systems. |

|

| |

| Features of

the RAJ Steam Tube Bundle Dryer : |

|

Operation is fully

automatic with low maintenance. |

|

Reduced wear and tear of parts. |

|

Less space requirements. |

|

Minimum air flow giving the

reduced output of waste air. |

|

Fire risk eliminated. |

|

Simple installation &

robust Construction. |

|

Safe Operation. |

|

Low temperature drying for

high quality products to avoid losses of vitamins,

nutrients and taste change. |

|

Mild steel or stainless steel

and constructions as required |

|

| |

|

| Applications

: |

|

| |

|

| Distillery Industry

: Drying of distillers grains. |

| |

| Extraction Industry

: |

Conditioning

of broken soya beans, sunflower seeds, whole or

flaked rape and other oilseeds. Pre -desolventizing

of oilseed coarse meal prior to the toaster.Drying

of oilseed coarse meal after the toaster. |

| |

| Brewing Industry

: Drying of spent grains. |

| |

| Chemical and

Plastics Industries: Drying of granulates |

| |

| Wood processing

industry : Drying of wood chips. |

| |

| Environment

processing : For disposal of liquid sewage,

waste water and paper sludge |

| |

| Other :

In many of these cases the materials viscosity is

improved by partial recycling. |

|

| |

| |

|

|

|